IMS Messsysteme GmbH is sending a clear signal about its growth trajectory and long-term location strategy in Germany: another test facility is currently being built at its headquarters in Heiligenhaus to expand production capacities.

Heiligenhaus, August 2025

Mr Beck, at Steel Dynamics, SDI Butler, you use the surcon 2D surface inspection system from IMS Messsysteme GmbH on the hot rolling mill. Could you give a brief description of your experience working with the system?

Of course. We have been very pleased with the results of IMS Messsysteme GmbH’s surcon 2D surface inspection system on the hot rolling mill. We use inspection systems from other manufacturers in other company locations, which has allowed me to compare the systems directly, and I believe the IMS system is far superior.

Why did you decide to use the IMS surface inspection system and what expectations did you have?

We were in contact with IMS about another technical solution, originally, and the surcon 2D surface inspection system was presented to us during these discussions. The surcon surface inspection systems were still relatively new at the time, but we quickly recognised the potential to significantly reduce our complaint rate. We were already using systems from other manufacturers for the same task in other plants, but the case for the innovative technology offered by IMS was a very strong one.

The solution has made an important contribution to a significant breakthrough in our quality assurance, especially since converting to a line scan camera in 2016. The improvements in precision and efficiency helped us reach a new level in terms of product quality.

So the aim was to reduce your complaint rate. Could you give us concrete numbers?

I can’t give you an exact amount in dollars, but looking back, we used to have complaints about approx. 6,000 to 8,000 tonnes a month. Today, we’re down to 200 to 300 tonnes or less.

And you use the system to evaluate complaints?

Exactly. Our sales representatives often ask me to check the surface quality of certain coils in the system’s long term data storage in order to establish whether the surface defects reported by a customer originated during the manufacturing process.

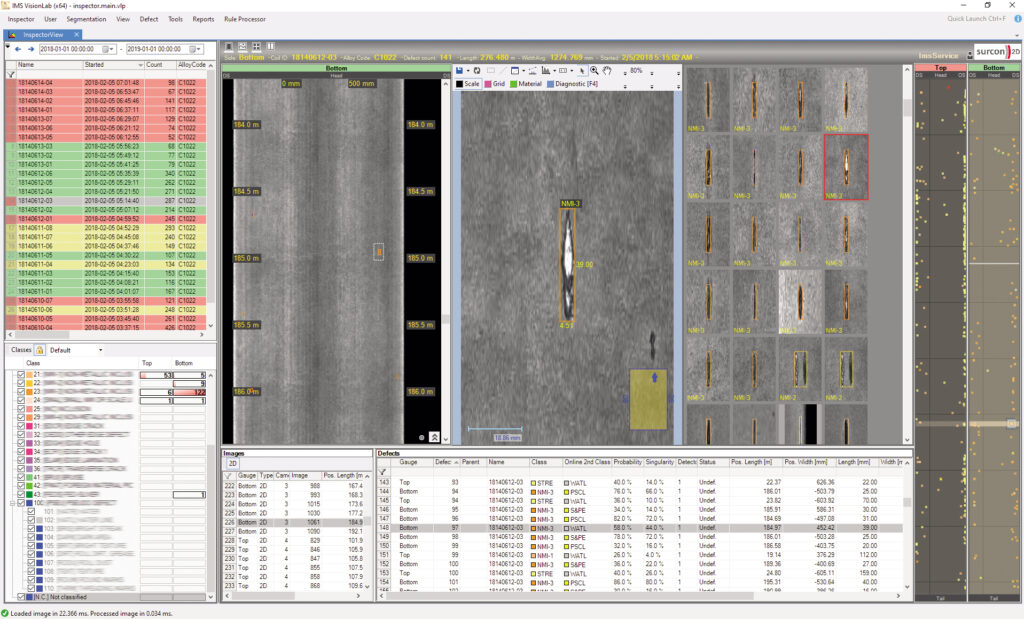

In many cases, I can prove that the defects are not the result of our production process thanks to the surface inspection system. This is a real advantage of the system – its inspection is incredibly accurate. By looking at the visualisation of results, I can immediately tell if a defect occurred after the inspection system, i.e. in later production stages, or at the plant, i.e. upstream of the system.

I have been dealing with surface defects for 30 years. Over time, you develop a feeling for the origin of certain defects and understand which specific stages of the process you have to look into.

The surface inspection system allows you to prove that a certain surface defect did not occur during hot rolling and reject the complaint?

That’s right. But the system offers even more savings potential. Let me give you an example: As the strip runs through our rolling mill, it chafes at the side guards. This causes abrasion to accumulate and eventually fall onto the strip. These particles are then rolled into the strip at the next roller and remain there in the final product.

Before installing the inspection system, we weren’t even aware of the problem. We’d had complaints about scrap marks, but we weren’t able to identify where they came from.

The surface inspection system enabled us to draw conclusions on a potential cause in the upstream production stages. Our suspicions were confirmed: By installing new, unused roller guides, we were able to greatly reduce the problem – while also making significant cost savings. In the past four years, we have had hardly any complaints.

You have to be careful with these numbers, but we have been able to reduce the share of coils with foreign objects from 20 percent per shift to just 3 to 5 percent or less – all thanks to the surcon 2D surface inspection system. Foreign particles in the strip now only depend on the condition of the roller guides.

A few weeks ago, some coils didn’t pass the quality inspection due to rolled-in particles. As we weren’t able to replace the roller guides immediately during ongoing production, we had to wait for a pause in operation. But thanks to the surface inspection system, we were able to identify the affected coils in time, before they were delivered.

You started working with the surface inspection system as the main responsible in 2018, but the system was first commissioned back in 2012. Were you still working as an operator in the hot rolling mill at the time?

That’s right. In 2012, I was working as an operator at the plant. I was responsible for machine setting and thus also for quality for a total of 21 years.

After the surface inspection system was installed in 2012, I first trialled it as a tool – but only the upper part, the beam above the strip, which we had installed for test purposes. The lower part of the system wasn’t added until 2014.

At the time, we wanted to test whether 2D surface inspection could really meet our requirements and just see if the test run would prove successful. And it did!

In those days, however, no one was able to work on optimising the system full time, although it is essential to continuously train the AI in surface inspection. Our steelworker only did this when his other tasks allowed.

After we updated the system to line scan cameras in 2016, a colleague of mine took over training the system and taught it to recognise new defects. Because this led to positive results very quickly, a specific position was created for the maintenance and further development of the surface inspection system. That’s my role today.

It shows how important the system now is in our production process.

Out of curiosity: How much did you use the surface inspection system in your time as an operator?

My colleague and I used the system a lot. It was completely new at first, of course, and changes aren’t always welcome, that applies to me too.

But the surface inspection system proved to be very helpful and quickly became a real success. The biggest challenge was to convince the other colleagues of its benefits. That took time. They had to learn to trust and embrace the new system.

Today, you use the system for quality assurance all the time. How do you use the 2D surface inspection system in your day-to-day work?

When I arrive at work in the morning, I first inspect all coils that the system has signalled as defective. Certain defects are categorised with specific lables. I check these carefully. I then only review the reported coils from the last 24 hours of production for approval. One big advantage of the inspection system is that new types of defects can easily be collected and included into the training database. This allows the system to learn continuously, which means that it can later classify these defects independently.

The most valuable function of the surface inspection system is probably the online view. It allows me to trace the strip back over time. I use this function regularly, as do the machine operators. Their equipment is identical to what I have in my office, so our quality management personnel in the individual shifts has the same possibilities as I do.

Screens are installed across the plant, at the coiler, for example, and in my office, of course. They all display real-time footage of the strip. Each coil has a live view that allows us to check the surface at all times.

This is incredibly helpful. Thanks to the online view, even from a distance, you can check whether process-related surface defects such as roll marks are being reported. Those defects have to be corrected as quickly as possible to minimise the scrap rate – fast response times are essential.

This means that your colleagues also work closely with the surface inspection system?

Definitely. Our internal bonus system incentivises my colleagues to use the system consistently. And if it ever stops working, they inform me immediately. But that rarely happens. It’s this high reliability that has continuously built our trust in the surface inspection system.

I am responsible for the maintenance of the system and I have now come to a point where it hardly requires maintenance. Even the underside inspection behind the cooling line is very reliable thanks to mechanical protection measures and needs very little maintenance.

How difficult was it for you to learn how to operate the surface inspection system, and how complicated is it to optimise the system’s classifier?

I did have to learn a few things at first; I’m not a natural at computers. But I saw coming to understand the system as an interesting challenge. Still, even without an in-depth understanding of machine learning, I was able to learn how to import defects and successfully train the surface inspection system’s AI.

Whenever I have questions or run into issues, I can always rely on the support of IMS, be it by telephone, video conference or through service visits.

The system is perfectly suited to my field of activity. It is surprisingly easy to operate and much less complicated than what I have seen of similar surface inspection systems outside our location or on the cold rolling mill.

You’re familiar with comparable products from competitors. What could IMS do to improve our system based on your experience with those competitors?

I can only speak from my own experience: We have achieved very good results with the IMS system on our hot rolling mill. We had the opportunity to examine another renowned manufacturer’s system in one of our sister plants. The concepts sounded promising in theory, but we are mainly interested in the practical application of solutions.

Our colleagues from the cold rolling mill have had good experiences with other systems, but hot rolling poses additional challenges, especially due to the harsh operating environment.

The surface inspection system offered by IMS is a solution that is much more convincing for us in these areas. It offers user-friendly operation and reliable defect recognition – two aspects that make a real difference in our daily work.

I believe that the IMS surface inspection system is the best overall solution for hot rolling mills and is well ahead of everything the competition has to offer.

About the company

Since 1980, X-ray, isotope and optical measuring systems of the globally leading producer IMS Messsysteme GmbH ensure highest product quality in the production and processing of steel, aluminium and non-ferrous metal.

The impressive portfolio of high-precision, perfectly coordinated and customisable measuring systems is worldwide unique in this scope; our solutions substantially contribute to optimised process sequences, increased output, reduced scrap rates and thus an economical, profitable and more environmentally compatible production.

Today, more than 4,500 non-contact IMS measuring systems are an integral part of the production equipment of hot mills, cold mills, process lines, plate mills, long-product rolling mills and tube rolling mills as well as metal service centres.